Zeziphi iintlobo zezixhobo zokubumba inaliti?

Isitofu sokubumba yinkqubo yokuvelisa ebandakanya ukutofa izinto ezinyibilikisiweyo kumgodi wokungunda ukuvelisa imilo efunekayo.Isitofu sokubumba singasetyenziselwa ukwenza iimveliso ezahlukeneyo, njengamacandelo eplastiki, amacandelo esinyithi, izixhobo zonyango, kunye nokunye.Nangona kunjalo, ayizizo zonke izixhobo ezifanelekileyo zokubumba inaliti.Siza kuxoxa ngeentlobo zezinto zokubumba iinaliti kunye neempawu zazo, iingenelo kunye nokungalunganga.

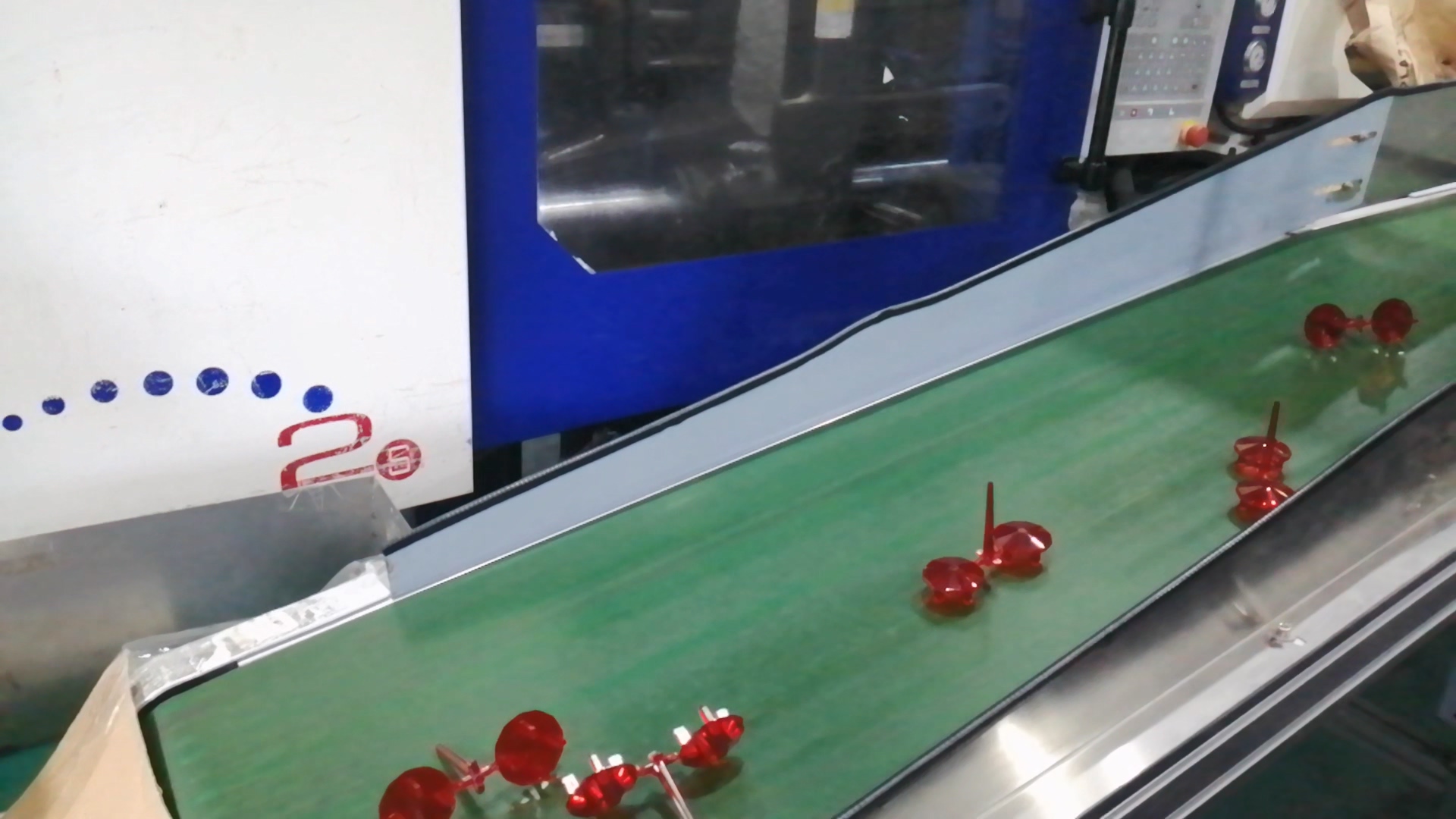

Iintlobo zezinto zokubumba zenaliti

Zininzi iintlobo zezixhobo zokubumba inaliti, kodwa zinokuhlelwa ngokubanzi zibe ziindidi ezine: thermoplastics, thermosets, elastomers, and metals.

Thermoplastics

I-Thermoplastics zizinto ezinokuncibilika ngokuphindaphindiweyo kwaye ziqiniswe ngokufudumeza kunye nokupholisa.Zezona ntlobo zixhaphakileyo zezinto zokubumba inaliti, zibalelwa malunga ne-80% yemarike.I-Thermoplastics inokuguquguquka okuphezulu, ukuqina, kunye nokuphinda kusetyenziswe.Eminye imizekelo ye-thermoplastics yile:

- I-Polyethylene (PE): Isixhobo esinexabiso eliphantsi esinokuchasana kakuhle neekhemikhali, umswakama kunye nefuthe.Isetyenziswa ngokubanzi ukupakishwa, izitya, iithoyi, kunye nemibhobho.

- Polypropylene (PP): Isixhobo esinokuqina okuphezulu, amandla, kunye nokumelana nobushushu.Isetyenziselwa iinxalenye zeemoto, izixhobo zonyango, ifenitshala, kunye nezixhobo zombane.

-Ipolyvinyl chloride (PVC): Yimathiriyeli ekwaziyo ukugquma umbane kakuhle, ukungakhathali kwedangatye, kunye nobume bezulu.Isetyenziselwa iintambo zombane, imibhobho, izifakelo, kunye nomgangatho.

- I-Polystyrene (PS): Isixhobo esinokucaca kakuhle, ukuqina, kunye nokuzinza kwe-dimensional.Isetyenziselwa iikomityi ezilahlwayo, iipleyiti, izinto zokucheba, kunye nokupakishwa.

- Acrylonitrile butadiene styrene (ABS): Isixhobo esinamandla empembelelo entle, ukuqina, kunye nokugqiba komphezulu.Isetyenziselwa izindlu, izigcina-ntloko, iithoyi, kunye nezixhobo zomculo.

Inayiloni: Isixhobo esinokumelana ne-abrasion elungileyo, ukuxhathisa ukunxiba, kunye neempawu zoomatshini.Isetyenziselwa ukwenza iigiya, iibheringi, iibhutsi kunye nezibophelelo.

Thermosets

I-Thermosets zizinto ezithatha i-chemical reaction xa zifudumala kwaye zenze imilo esisigxina engenako ukunyibilika okanye ukubunjwa kwakhona.I-Thermosets inozinzo oluphezulu lwe-thermal, ukumelana neekhemikhali, kunye namandla omatshini.Eminye imizekelo ye-thermosets yile:

-I-Epoxy: Isixhobo esinokuncamathela okugqwesileyo, ukugqunywa kombane, kunye nokumelana nomhlwa.Isetyenziselwa ukwambathisa, izinto zokuncamathelisa, i-laminates, kunye ne-composites.

-I-Phenolic: Isixhobo esinokumelana nobushushu obuphezulu, ukubuyiswa komlilo, kunye nokuqina.Isetyenziselwa ukutshintsha kombane, iisokethi, iiplagi, kunye nezibambo.

-Ipolyester: Isixhobo esinokuguquguquka okuhle, ukuqina, kunye nemozulu.Isetyenziselwa ukwakhiwa kweenqanawa, imizimba yeemoto, iitanki kunye nemibhobho.

I-Urea formaldehyde: Isixhobo esinexabiso eliphantsi, ukuqina okuphezulu, kunye nokuzinza okuhle kwe-dimensional.Isetyenziselwa amaqhina, amaqhosha,

izibambo, kunye nefenitshala.

Iielastomers

Ii-elastomers zizinto ezinokuthi zolulwe okanye zicinezelwe kwaye zibuyele kwisimo sazo sokuqala xa amandla asusiwe.Iielastomers zinokuqina okuphezulu,

ukomelela, kunye nokufunxa ukothuka.Eminye imizekelo yee-elastomers yile:

-I-Silicone: Isixhobo esinokuxhathisa ubushushu, ukuxhathisa kwe-ozone, kunye ne-biocompatibility.Isetyenziselwa itywina, iigaskets, iityhubhu, kunye nezixhobo zonyango.

-Irabha: Isixhobo esinokumelana ne-abrasion elungileyo, ukuxhathisa ukudinwa, kunye ne-vibration damping.Isetyenziselwa amatayara, iibhanti, iihosi kunye neegrommets.

I-Thermoplastic elastomers (TPEs): Isixhobo esidibanisa iimpawu ze-thermoplastic kunye ne-elastomers.

Iintsimbi

Izinyithi zizinto ezine-conductivity ephezulu, ingxinano, kunye neqondo lokunyibilika. Ngokuqhelekileyo zifakwe kwi-mold ngokusebenzisa inkqubo ekhethekileyo ebizwa ngokuba yi-metal injection molding (MIM) .I-MIM ibandakanya ukuxuba i-powders yensimbi kunye nezibophelelo ukwenza i-feedstock enokuthi ifakwe kwisitofu. i-mold.Indawo ebunjiweyo ifudunyezwe ukususa izibophelelo kunye ne-sintered ukwenza inxalenye yentsimbi eshinyeneyo.I-MIM inokuvelisa iimilo ezintsonkothileyo kunye nokuchaneka okuphezulu, ukugqitywa komphezulu, kunye neempawu zoomatshini.Eminye imizekelo yesinyithi enokusetyenziswa kwi-MIM yile:

-Intsimbi engatyiwayo: Isixhobo esinokumelana nomhlwa okuphezulu, ukomelela, kunye nokuqina.Isetyenziselwa izixhobo zotyando, ukufakelwa kwamazinyo, ubucwebe, kunye neewotshi.

I-Titanium: Isixhobo esinomlinganiselo ophezulu wokuqina kobunzima, ukuhambelana kwebhayoloji, kunye nokumelana nobushushu. Isetyenziselwa izinto ze-aerospace, izixhobo zemidlalo, ukufakelwa kwamazinyo, kunye nezixhobo zonyango.

-Intsimbi: Isixhobo esinexabiso eliphantsi, iipropathi zemagnethi, kunye nokumelana nokunxiba.Isetyenziselwa iinxalenye zemoto, izixhobo zamandla, iigiya kunye neebheringi.

Ukuqukumbela

Ukubunjwa kwe-injection yinkqubo eguquguqukayo enokuvelisa iindidi zeemveliso usebenzisa iintlobo ezahlukeneyo zezinto eziphathekayo.Udidi ngalunye lwezinto luneempawu zalo,

izinto eziluncedo, kunye nezingeloncedo.Ngoko ke, kubalulekile ukukhetha imathiriyeli efanelekileyo kwisicelo esithile kunye neemfuno zoyilo.Ukwenziwa kwesitofu kunokudityaniswa nezinye iinkqubo, ezinje ngokufaka ukubumba, ukugoqa, kunye ne-co-injection, ukwenza izinto ezininzi. okanye iimveliso ezinemibala emininzi.I-injection molding yindlela ekhawulezayo, esebenzayo, kunye nexabiso eliphantsi lokwenza iimveliso ezikumgangatho ophezulu.

Yintoni ukubumba inaliti?

Isitofu sokubumba yinkqubo yokuvelisa evelisa iinxalenye zeplastiki ngokutofa izinto ezityhidiweyo kumngundo.Inkqubo iquka izigaba ezine eziphambili: i-clamping, i-injection, ukupholisa kunye ne-ejection.

Ukubamba: Ukungunda kwenziwa ziziqingatha ezibini, ezibizwa ngokuba ngumngxuma kunye nombindi, ezincanyathiselwe kwiyunithi yokubambelela.Iyunithi ye-clamping ibamba i-mold ivaliwe phantsi koxinzelelo ngexesha lokutofa kunye nezigaba zokupholisa.Amandla okubamba axhomekeke kubukhulu kunye nokumila kwenxalenye, kunye nezinto ezisetyenzisiweyo.

I-injection: Izinto zeplastiki, ngokuqhelekileyo ngendlela yeepellets okanye iigranules, zondliwa kwi-barrel evuthayo, apho iyancibilika kwaye ixutywe nge-screw ejikelezayo.Isikrufu sikwasebenza njengeplunger, sityhala iplastiki enyibilikisiweyo kwisingundo ngokusebenzisa umlomo.Isantya sokutofa, uxinzelelo kunye nobushushu zilawulwa ukuze kuqinisekiswe ukuba izinto eziphathekayo zigcwalisa isikhunta ngokupheleleyo kwaye ngokulinganayo.

Ukupholisa: Iplastiki etyhidiweyo ngaphakathi komngundo iqala ukupholisa kwaye iqine, ithatha ubume benxalenye.Ixesha lokupholisa lixhomekeke kubukhulu kunye nejometri yecandelo, kunye neempawu zezinto eziphathekayo.Ngeli nqanaba, isikhunta sihlala sivaliwe kwaye siphantsi koxinzelelo lokuthintela ukuncipha okanye ukuguqulwa.

Ukukhutshwa: Emva kokuba inxalenye ipholile ngokwaneleyo, ukubumba kuyavulwa kwaye inxalenye ikhutshwe yinkqubo ebizwa ngokuba yi-ejector system.Inkqubo ye-ejector ingaba izikhonkwane, ii-blades okanye iijethi zomoya ezityhala inxalenye ngaphandle kokubumba.Emva koko inxalenye iyasuswa kumatshini kwaye ihlolwe umgangatho.

I-injection molding yinkqubo eguquguqukayo kwaye esebenzayo enokuthi ivelise iindawo ezinzima kunye nekhwalithi ephezulu ngobuninzi kunye nenkunkuma ephantsi.Isetyenziswa kakhulu kumashishini ahlukeneyo, njengeemoto, ezonyango, iimpahla zabathengi, i-elektroniki kunye nokunye.

Yintoni ukubaluleka kunye nendima yokungunda inaliti?

Isitofu sokubumba yinkqubo yokuvelisa esetyenziswa ngokubanzi enokuvelisa iinxalenye zeplastiki ezinemilo enzima kunye nokuchaneka okuphezulu.Ukubumba isitofu kubandakanya ukutofa iplastiki enyibilikisiweyo kumngxuma wokungunda, apho ithi iphole ize iqine ibe kukumila okufunekayo.Umgodi wokungunda udla ngokwenziwa ngentsimbi okanye ngeceramic, kwaye unokuyilwa ukuvelisa iindawo ezininzi ngaxeshanye.

Ukubaluleka kunye nendima yokubumba inaliti ibalulekile kumashishini amaninzi, njengeemoto, ezonyango, i-aerospace, i-electronics yabathengi, kunye nokunye.Ukubumba isitofu kunokubonelela ngeengenelo ezininzi, ezinje:

- Ukusebenza okuphezulu kwemveliso: I-injection yokubumba inokuvelisa ubuninzi beengxenye ngexesha elifutshane, kunye nenkunkuma encinci kunye ne-scrap.Imishini yokubumba i-injection inokusebenza ngokuqhubekayo, kwaye iyakwazi ukuzenzekelayo ukunciphisa iindleko zabasebenzi kunye neempazamo zabantu.

- Umgangatho ophezulu kunye nokuhambelana: Ukubunjwa kwe-injection kunokuvelisa iindawo ezinobungakanani obuchanekileyo kunye nokugqiba umphezulu, kunye neempawu ezifanayo kunye nokusebenza.Ukubunjwa kwe-injection kunokunciphisa iziphene kunye nokwahluka kwimveliso yokugqibela, ngokulawula ubushushu, uxinzelelo, kunye nesantya senkqubo yokutofa.

- Ukuguquguquka koyilo: Isitofu sokubumba sinokuvelisa iindawo ezinejometri ezintsonkothileyo, iinkcukacha ezintsonkothileyo, kunye nemibala emininzi okanye imathiriyeli.Ukubunjwa kwe-injection kunokwamkela utshintsho kuyilo okanye iinkcukacha zamalungu, ngokuguqula i-mold cavity okanye ukusebenzisa izinto zeplastiki ezahlukeneyo.

- Ukusebenza kweendleko: I-injection molding inokunciphisa iindleko ezipheleleyo zokuvelisa, ngokunciphisa ukusetyenziswa kwezinto eziphathekayo, ukunciphisa ukudibanisa kunye nokugqiba imisebenzi, kunye nokwandisa ukuqina kunye nokuphila kwamacandelo.

I-injection molding yinkqubo yokwenza izinto ezininzi kwaye inokuthenjwa enokuthi ihlangabezane neemfuno zamashishini ahlukeneyo kunye nezicelo.Nangona kunjalo, ukubumba inaliti kunemingeni kunye nemida, efana nale:

- Utyalo-mali oluphezulu lokuqala: I-injection yokubumba ifuna ixabiso eliphezulu eliphezulu lokuyila kunye nokwenza i-mold cavity, kunye nokuthenga nokugcina umatshini wokubumba inaliti.Umgodi wokungunda uqhele ukwenziwa ngokwezifiso kwindawo nganye, kwaye unokubiza kwaye utya ixesha ukuvelisa.

- Ukukhethwa kwezinto ezilinganiselweyo: I-injection molding inokusebenzisa kuphela izinto ze-thermoplastic ezinokunyibilika kunye nokuhamba phantsi kobushushu obuphezulu kunye noxinzelelo.Ezinye izixhobo ze-thermoset okanye izinto ezihlanganisiweyo zisenokungakulungeli ukubumba inaliti, okanye zinokufuna izongezo ezikhethekileyo okanye unyango ukuphucula ukubumba kwazo.

- Impembelelo yokusingqongileyo: Isitofu sokubumba sinokuvelisa ubushushu obuninzi benkunkuma kunye nokukhutshwa ngexesha lokunyibilika kunye nokupholisa izinto zeplastiki.Ukubumba isitofu kunokuvelisa inkunkuma yeplastiki ukusuka kwizinto ezigqithileyo eziphuma kumngxunya okanye zenze imiphetho yenxalenye.Le nkunkuma kufuneka ihlaziywe okanye ilahlwe ngokufanelekileyo, ukunciphisa impembelelo yazo yokusingqongileyo.

Isitofu sokubumba yinkqubo entsonkothileyo neguqukayo efuna ukucwangciswa ngononophelo, uyilo, kunye nokuphucula.Iinjineli zokubumba ii-injection kufuneka ziqwalasele izinto ezininzi, ezinje:

- Ukukhetha izinto eziphathekayo: Ukukhethwa kwezinto zeplastiki kuchaphazela iipropati, ukusebenza, ukubonakala, kunye neendleko zecandelo lokugqibela.Izinto zeplastiki kufuneka zihambelane neemfuno zomsebenzi wenxalenye, indawo engqongileyo, ubuhle kunye nokuqina.Izinto zeplastiki kufuneka zibe nokuhamba kakuhle, ukuzinza, ukushwabana, kunye nokuhambelana nomgodi wokungunda.

- Uyilo lokungunda: Uyilo lomgodi wokungunda lumisela imilo, ubungakanani, umgangatho, kunye nobunzima benxalenye yokugqibela.Umgodi wokungunda kufuneka ube neenkqubo ezaneleyo zokukhupha umoya, ukupholisa, ukukhupha, kunye nezokubamba, ukuqinisekisa inkqubo yokutofa egudileyo nesebenzayo.Umgodi wokungunda kufuneka ube nee-engile ezifanelekileyo zoyilo, ubukhulu bodonga, ukunyamezela, kunye nokugqitywa komphezulu, ukukhusela iziphene kunye nokukhubazeka kwinqanaba lokugqibela.

-Iiparamitha zenkqubo: Izicwangciso zenkqubo yokutofa zichaphazela indlela yokuziphatha, izinga lokupholisa, ukusabalalisa uxinzelelo, kunye nekristali yezinto zeplastiki.Iiparamitha zenkqubo kufuneka zilungiswe ukuze kulungiswe ukuzaliswa, ukupakisha, ukubamba, ukupholisa, kunye nokukhupha izigaba zenkqubo yokutofa.Iiparamitha zenkqubo kufuneka kwakhona zibekwe iliso kwaye zilawulwe ukugcina ukuhambelana kunye nomgangatho kwimveliso yokugqibela.

Isitofu sokubumba yinkqubo yokuvelisa enamandla nethandwayo enokudala iinxalenye zeplastiki ezikumgangatho ophezulu ezinemilo eyahlukeneyo kunye nemisebenzi.Ukubunjwa kwe-injection kudlala indima ebalulekileyo kumashishini amaninzi axhomekeke kwiimveliso zeplastiki ngokusebenza kwazo kunye nenzuzo.Isitofu sokubumba sikwayinkqubo engumceli mngeni kunye nephuhlisayo efuna ukusungulwa rhoqo kunye nokuphuculwa kokuhlangabezana neemfuno eziguqukayo kunye nokulindelwe ngabathengi.