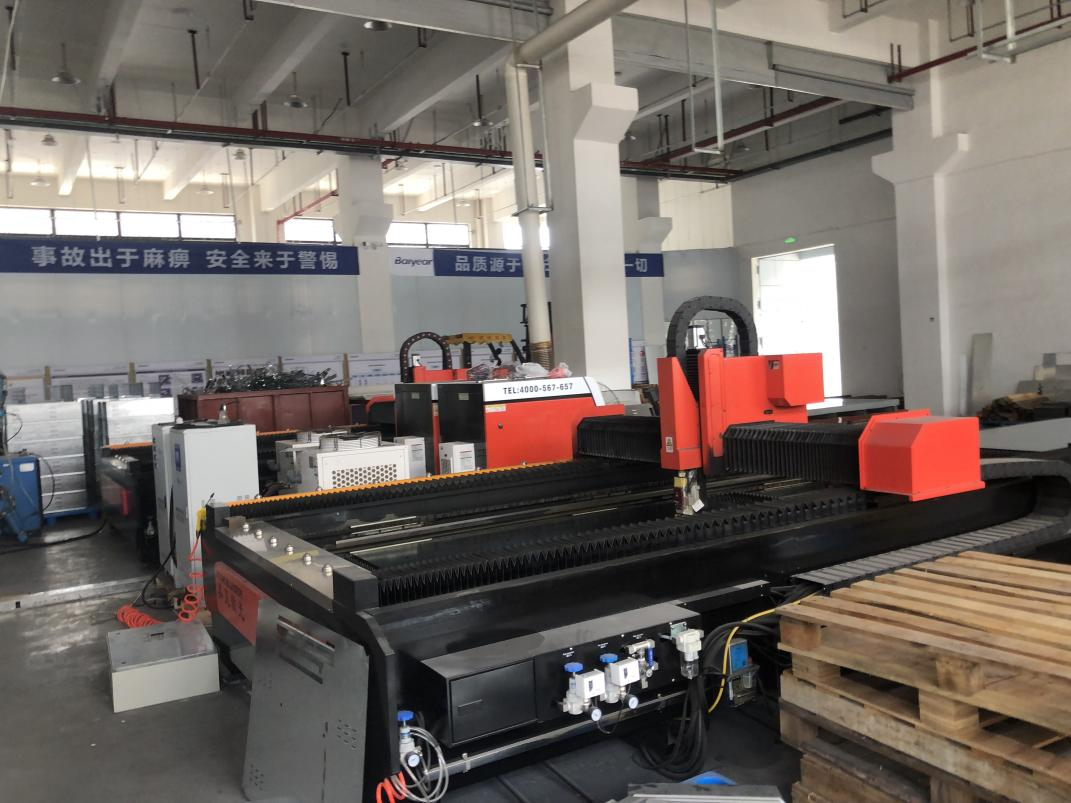

NguAndy osuka kumzi-mveliso waseBaiyear

Ihlaziywe ngoNovemba 1, 2022

Icwecwe lesinyithi alikabi nayo inkcazo epheleleyo.Ngokutsho kwenkcazo kwijenali yobungcali yangaphandle, inokuchazwa njenge: Ishiti lesinyithi yinkqubo yokusebenza ebandayo ebanzi yeepleyiti zentsimbi ezibhityileyo (ngokuqhelekileyo zingaphantsi kwe-6mm), kubandakanywa ukucheba, ukubethelwa / ukusika / ukuhlanganisa, ukusonga, ukuwelda, i-riveting, i-splicing , ukubumba (okufana nomzimba wemoto), njl. Into ephawulekayo kukuba ubukhulu becala elifanayo bufana.

Ukusika isinyithi yinkqubo ebalulekileyo yokwenza iimveliso zentsimbi.Ibandakanya ukugawula zemveli, blanking, ukugoba ukubumba kunye nezinye iindlela kunye nenkqubo parameters, kwakunye nezakhiwo ezahlukeneyo ebandayo stamping die kunye nenkqubo parameters, imigaqo yokusebenza izixhobo ezahlukeneyo kunye neendlela zokusebenza, kwakunye neteknoloji entsha stamping kunye nobuchwepheshe obutsha .

Kuyo nayiphi na inxalenye yentsimbi, inenkqubo ethile yokucubungula, ebizwa ngokuba yinkqubo yezobuchwepheshe.Ngokwahlukileyo kwisakhiwo samacandelo e-sheet metal, inkqubo yezobuchwepheshe inokuthi ihluke, kodwa iyonke ayidluli amanqaku alandelayo.

1. Yila kwaye uzobe umzobo wenxalenye yamacandelo ayo esinyithi, eyaziwa ngokuba ziimbono ezintathu.Umsebenzi wayo kukubonakalisa ubume becala lentsimbi yentsimbi ngokusebenzisa imizobo.

2. Zoba umzobo ongasombulukanga.Oko kukuthi, tyhila inxalenye enesakhiwo esiyinkimbinkimbi ibe yindawo ethe tyaba.

3. Ukungabi nanto.Zininzi iindlela zokuvala, ikakhulu ngezi ndlela zilandelayo:

a.Ukucheba umatshini wokucheba.Kukusebenzisa umatshini wokucheba ukusika imilo, ubude nobubanzi bomzobo owandisiweyo.Ukuba kukho i-punching kunye nokusika ikona, ke ujike umatshini wokubhoboza ukudibanisa ukufa kunye nokusika ikona ukwenza ifom.

b.Ingqindi engenanto.Kukusebenzisa i-punch ukubetha i-flat part structure emva kokuba iinxalenye zityhilwe kwi-plate kwinqanaba elinye okanye ngaphezulu.Ineenzuzo zeeyure zomntu ezimfutshane, ukusebenza kakuhle okuphezulu, kwaye inokunciphisa iindleko zokucubungula.

c.I-NC CNC engenanto.Xa NC blanking, inyathelo lokuqala kukubhala CNC inkqubo machining.Kukusebenzisa isoftware yokucwangcisa ukubhala umzobo ozotyiweyo wokwandisa ube yinkqubo enokwamkelwa ngumatshini womatshini weNC CNC.Yiyeke ilandele ezi nkqubo inyathelo ngenyathelo kwipleyiti yentsimbi On, gqobhoza ubume besakhiwo seendawo zayo ezisicaba.

d.Ukusika kweLaser.Isebenzisa indlela yokusika i-laser ukusika ubume besakhiwo seendawo zayo ezisicaba kwipleyiti yentsimbi.

4. Ukubetha nokucofa.I-Flanging ikwabizwa ngokuba kukugrumba umngxuma, nto leyo kukuzoba umngxuma omkhudlwana kumngxuma osisiseko omncinci, emva koko ucofe umngxuma.Oku kunokonyusa amandla ayo kwaye kuphephe ukutyibilika.Ngokubanzi isetyenziselwa ukusetyenzwa kwentsimbi enobungqingqwa bepleyiti encinci.Xa ubukhulu bepleyiti bukhulu, obufana nobukhulu beplate ngaphezu kwe-2.0, 2.5, njl., sinokucofa ngokuthe ngqo ngaphandle kwe-flanging.

5. Punch processing.Ngokuqhelekileyo, ukubetha kunye nokusika ikona, ukubethelwa kwe-punching, ukubethelela i-convex hull, ukubethelwa kunye nokukrazula, ukubethelwa kunye nezinye iindlela zokucubungula zisetyenziselwa ukufezekisa injongo yokucubungula.Ukulungiswa kufuna ukubumba okuhambelanayo ukugqiba umsebenzi.Kukho iimolds ze-convex hull zokubethelela i-convex i-convex, kunye nokukrazula ukubumba okubumba ukubethelwa kunye nokukrazula.

6. Ukunyusa uxinzelelo.Ngokubhekiselele kwifektri yethu, i-pressure riveting studs, i-riveting nuts, i-pressure riveting screws, njl.Ihlanjululwe kwiindawo zentsimbi.

7. Ukugoba.Ukugoba kukusonga iindawo ezisicaba ze-2D zibe ngamalungu e-3D.Ukusetyenzwa kwayo kufuna umatshini wokugoba kunye nokufa okugoba okuhambelanayo ukugqiba umsebenzi.Ikwanalo nolandelelwano oluthile lokugoba.Ukugotywa kokuqala okungaphazamisiyo kuya kuvelisa ukugoba kokugqibela okuphazamisayo.

8. Ukuwelda.Ukuwelda kukudibanisa iinxalenye ezininzi kunye ukufezekisa injongo yokusetyenzwa okanye ukuwelda umthungo osecaleni wenxalenye enye ukwandisa amandla ayo.Iindlela zokucubungula ngokubanzi ziquka oku kulandelayo: i-CO2 yegesi ekhuselekileyo ye-welding, i-argon arc welding, i-Spot welding, i-robot welding, njl.Ngokuqhelekileyo, i-CO2 yegesi ekhuselweyo isetyenziselwa ukuwelda ipleyiti yentsimbi;i-argon arc welding isetyenziselwa i-aluminium plate welding;i-robot welding isetyenziswa kakhulu kwizinto eziphathekayo Isetyenziswa xa iindawo zikhulu kwaye i-welding seam inde.Okufana nekhabhinethi yelding, i-robot welding ingasetyenziswa, enokugcina imisebenzi emininzi kunye nokuphucula ukusebenza kakuhle kunye nomgangatho we-welding.

9. Unyango lomphezulu.Unyango oluphezulu ngokubanzi lubandakanya ifilimu ye-phosphating, i-electroplating multicolored zinc, chromate, ipeyinti yokubhaka, i-oxidation, njl. Ifilimu ye-Phosphating isetyenziselwa ngokubanzi amashiti aqengqelekayo kunye namaphepha e-electrolytic, kwaye umsebenzi wayo ubukhulu becala ukwambathisa umphezulu wezinto.Ifilimu ekhuselayo isetyenziselwa ukukhusela i-oxidation;okwesibini kukuphucula ukunamathela kwepeyinti yayo yokubhaka.Electroplating ezimibalabala zinc ngokuqhelekileyo isetyenziselwa unyango umphezulu iipleyiti eziqengqelekayo ebandayo;ichromate kunye ne-oxidation zisetyenziswa ngokubanzi kunyango lomphezulu lweepleyiti ze-aluminium kunye neeprofayili ze-aluminium;indawo yayo ethile Ukhetho lwendlela yokucubungula lumiselwa ngokweemfuno zomthengi.

10. INdibano.Oku kubizwa ngokuba yindibano kukudibanisa amalungu amaninzi okanye amacandelo kunye ngendlela ethile ukuze abe yinto epheleleyo.Enye yezinto ekufuneka ziqwalaselwe kukukhuselwa kwezinto eziphathekayo, kungekhona imikrwelo kunye namaqhuma.INdibano linyathelo lokugqibela ekugqityweni kwezinto.Ukuba izinto eziphathekayo azikwazi ukusetyenziswa ngenxa yokukrazula kunye nama-bumps, kufuneka zihlaziywe kwaye zihlaziywe, eziza kuchitha ixesha elininzi lokucubungula kunye nokwandisa iindleko zento.Ngoko ke, ingqalelo ekhethekileyo kufuneka ihlawulwe ekukhuselweni kwento.

Ixesha lokuposa: Nov-29-2022