NguAndy osuka kumzi-mveliso waseBaiyear

Ihlaziywe ngoNovemba 5, 2022

Ngokuphathelele ukuqaliswa kwamanyathelo athile okuvelisa i-mold, siye sahlula kumanqaku e-2 ukwazisa, eli linqaku lesibini, umxholo ophambili: 1: I-Plastiki yeSitofu yeSiko le-2: I-Factory Mold Ukwenza i-3: I-Plastiki Injection Mold 4: Isitofu sokubumba ngokuchanekileyo 5: umenzi weplastiki yokufa 6: uyilo lokubumba lokubumba inaliti 7: ukwenza ukubumba kunye nokuphosa 8: inkqubo yokwenza ubumba

7. Ukucima ukungunda kwangaphakathi

(1), sebenza ngaphambi kokucima

a) Ukugrumba umngxuma wombhobho: Gqoka umngxuma wombhobho kwidayiti ephezulu ngokweemfuno zomzobo.Xa ubhobhoza umngxuma we-nozzle kwifa ephezulu, nikela ingqalelo kwiziko elifanayo kunye nomngxuma ongezantsi.

b) Ukugrumba umngxuma we-shunt cone: Gqoka umngxuma we-shunt cone embindini wembaleki esezantsi ngokweemfuno zomzobo, emva koko ulungise ikhowuni ye-shunt, kwaye ugrumbe umngxuma wethimble kuyo.

c) Ukugrumba umngxuma wamanzi: Ngokweemfuno ze-icon, yomba umngxuma wamanzi (amanzi apholisayo) kwicala lokungunda kwangaphakathi.

d) Gqoka kwaye ucofe umngxuma wokulungisa (umngxuma oyimfama) kwindawo edibeneyo yokubumba yangaphakathi kunye nesakhelo sokubumba.

e) Ukuba kukho iinaliti kwi-mold yangaphakathi, imingxuma yenaliti kufuneka ibhojwe.

(2), yomba umngxuma wethawula

Iphini ye-ejector yinxalenye ebalulekileyo yomsebenzi womatshini wokubumba.Umsebenzi walo kukwahlula imveliso kwisiseko sokubumba ngokusebenzisa isenzo se-ejector somatshini webhiya, ukwenzela ukuba kuphunyezwe umphumo we-ejection jikelele.Ukuchaneka kokucubungula kwepini ye-ejector kuchaphazela ngokuthe ngqo umgangatho we-mold.kunye nobomi benkonzo.Iimfuno zenkqubo:

a) Indawo yokuma komngxuma wethontsi kufuneka iqwalaselwe ngokweemfuno zoyilo jikelele zemveliso, ukunqanda i-thimble-wall kunye neendawo ezichaphazela inkangeleko kangangoko kunokwenzeka.Ukuze uthintele umqheba webhiya (ithambeka) kwindawo yotshintsho, kunye nenaliti eyaphukileyo ngexesha lemveliso, kufuneka isetyenziswe ngaphambi kokugrumba umngxuma we-thimble.Gqoka incam ye-drill yecandelo elincinci ukusuka ezantsi, kwaye usebenzise incam ye-drill yecandelo elikhulu ukugqobhoza ukusuka kwicala elingasemva.

b) Xa usenza imingxunya, khangela ukuma phakathi kwee-axes zokomba kunye noomatshini bokugaya abasetyenziswayo kunye netafile yokusebenza.

c) Umngxuma wethimbi kufuneka ushiywe kunye nomda ngexesha lokusetyenzwa, ukuze kuqinisekiswe ukutshintshwa komatshini phakathi komngxuma kunye nethimble emva kokuphinda kuphindwe nge-reamer.Ukuba iqinile kakhulu, umngxuma kunye nethanga liya kutshiswa ngexesha lemveliso;Kukho imida.

d) Xa ubhobhoza umngxuma we-thimble, kufuneka kuqinisekiswe ukuba umngxuma wokuthuthwa kwamanzi awuyi kuchithwa.

e) Xa kusetyenzwa imingxunya engaphantsi kwe-1.5mm, ubude bendawo yokutshintsha kufuneka bugcinwe phakathi kwe-20mm kunye ne-30mm kangangoko ukuthintela imingxunya engenanto, kwaye ke icandelo elingenamntu (umsantsa ophakathi kwenwebu kunye nomngxuma wokuthunga) kufuneka kusetyenzwe.Umngxunya wokuphepha umngxuma kufuneka ube malunga ne-0.5mm enkulu kune-aperture yenguqu.Xa lilikhulu kakhulu, incanca ende kulula ukugoba nokuqhawuka.

(3), ukucima ukungunda kwangaphakathi

Emva kokuba i-mold yangaphakathi ilungile, ithunyelwa kwisityalo sokunyanga ukushisa ukucima, ukwenzela ukuba i-mold yangaphakathi ikwazi ukuhlangabezana neemfuno zobunzima.

8. Ukulahla isakhelo

(1), wisa isakhelo

Emva kokuba ukubunjwa kwangaphakathi kucinywe, kufakwe kwisakhelo sokubumba ukuze kuhlolwe ukulungelelanisa.Kule njongo, kuyimfuneko ukugaya kunye nokunciphisa umgca odibeneyo wesakhelo sokubumba kunye ne-mold yangaphakathi, ukwenzela ukuba i-mold yangaphakathi ikwazi ukuwa ngokupheleleyo kwisakhelo sokubumba kwaye ukuhambelana kuqhelekileyo.

(2) Gqoka imingxuma yokulungisa umngundo wangaphakathi kwisakhelo sokungunda

Krwela indawo yoncedo lwendawo kumngxunya ongaphakathi wokungunda, kwaye emva koko ucinezele ukubumba okungaphakathi kwisakhelo sokungunda, ukuze isixhobo esincedisayo siphawule embindini womngxuma kwisakhelo sokungunda.Emva koko khupha i-mold yangaphakathi kwaye ujike izixhobo ezincedisayo.Gqoka imingxuma kwisakhelo sokubumba ngokweempawu zokomba, kwaye ekugqibeleni ujike isakhelo sokubumba kwaye ubhoboze imingxuma.

9. Ukuguqula umgca kwakhona

Eli nyathelo lenziwa emva kokuba i-mold yangaphakathi iwiswe, kwaye injongo kukujonga ukulungelelaniswa kwamacala amabini omsebenzi osebenzayo womqolo kunye nokubumba kwangaphakathi.Faka ipeyinti ebomvu kwiindawo zecala le-mold yangaphakathi kunye nendawo yomqolo, faka indawo yomqolo, kwaye ucinezele indawo yomqolo kwindawo.Inxalenye echaseneyo yomqolo kufuneka iprintwe ngokupheleleyo ngepeyinti ebomvu, ngaphandle koko kufuneka iphuculwe, ilungiswe, kwaye ihlolwe ngokuphindaphindiweyo de ipeyinti ebomvu ishicilelwe ngokupheleleyo.

10. Ukucima umqolo

Emva kokuba umgca ulungile, ucinywa ukuze ufezekise iimfuno zobunzima.

11. Isitulo soxinzelelo (inkukhu ene-oblique)

(1), ukuthambeka kwesikhundla somqolo

Ngokweemfuno ze-icon kunye neemeko zobugcisa, i-plane ethambekeleyo icutshungulwa kwindawo yesilayidi yendawo yomqolo.

(2), isihlalo soxinzelelo

a) Ukuthambeka komqolo kunye nobukhulu befreyimu ephezulu yesakhelo sokubumba.

b) Gqoka imingxuma yokubeka kwisakhelo sokufa esingentla kunye nesitulo esicinezelayo ngokokuthambeka komqolo kunye nendawo yomqolo, kwaye ulungise isitulo esicinezelayo kwisakhelo sokungunda esiphezulu.

c) Gqoka umngxuma we-bevel kwindawo yomqolo, kwaye umngxuma we-bevel kufuneka ube yi-2 degrees encinci kune-bevel.

d) Gqoka imingxuma yokumisa ebhaviweyo kwidiyizi engaphezulu ngokwendawo kunye nokuthambekela kwemingxuma eqhawukileyo ebhodlwe kwindawo yomqolo, uze ufakele iincam ezibeveled ukujonga ulungelelwaniso.Umngxuma we-hypotenuse ngokubanzi ziintsapho ezi-2 ezinkulu kune-hypotenuse.

12, imodeli iyonke

Emva kokuba i-mold yangaphakathi, isikhundla somgca, inaliti yokufaka, kunye nesakhelo sokubumba zonke zihambelana, iimbumba eziphezulu kunye nezantsi zidibene ukuze zenze i-mold, kwaye i-molds yangaphakathi nangaphantsi, imiqolo kunye nokufakwa kuhlolwe ngepeyinti ebomvu., Lungisa ifosholo de ifakwe ngokupheleleyo.

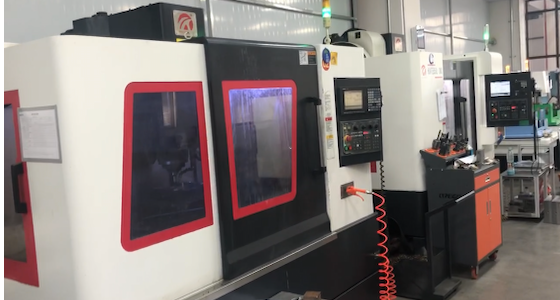

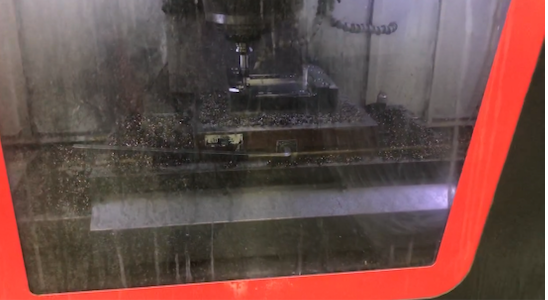

13. EDM machining

I-EDM isekelwe kumgaqo we-EDM.Xa indoda yobhedu kunye nesixhobo sokusebenza sisondelelene, i-voltage ye-inter-electrode iya kubangela ukuba i-electrolyte i-ionize kwaye iphuke kweyona ndawo ikufutshane phakathi kwee-electrode ezimbini ukwenza ukukhutshwa kwentlantsi, okukhokelela kumthamo omkhulu wamandla obushushu kwangoko. eveliswa kumjelo wentlantsi, isenza intsimbi inyibilike ngokuyinxenye, ide ibe ngumphunga, ibe ngumphunga ukuze ikhukulise isinyithi.Ingasetyenziselwa nayiphi na imathiriyeli eqhubayo ukwenza nayiphi na into eqinileyo, ethambileyo, encangathi okanye ephezulu yokunyibilika kwentsimbi, kubandakanya intsimbi enobushushu kunye nealloys, izixhobo ze-electrode (inkunzi yobhedu) kunye nesixhobo sokusebenza siphantsi kokutya kombane ukuvelisa umhlwa. (umphunga kwaye uqinile).I-corrosion yombane yendoda yobhedu iya kubangela ilahleko ye-electrode, kwaye ukubola kombane we-workpiece kuya kuyenza ihlangabezane neemfuno zokwenza ukuchaneka.

Iimfuno zenkqubo:

(1) Bambelela indoda yobhedu ngokuqinileyo kwi-spindle chuck yesixhobo somatshini, kwaye ulungelelanise indawo yereferensi ukuze ihlangabezane neemfuno zokuchaneka komatshini.Ezinye iinkunzi zobhedu ezinkulu nezicekethekileyo ezinamacala amathathu kulula ukukhubazeka kwaye zigobe ngexesha lokusetyenzwa, kwaye kufuneka zilungiswe ngokulungeleleneyo kwiinkunzi zobhedu ezine-tripod-type fixing clip.

(2) Faka i-workpiece kwitafile yomatshini kwaye ulungise ukuchaneka kwereferensi.

(3), ngokweemfuno zokucubungula inxalenye nganye ye-electro-rosion processing.

14. Ukumenyezwa (ukugcina ukufa)

Ukugulisa umngundo kukusetyenzwa komngxuma wokungunda kunye nokugqiba okungundoqo kwiimfuno zembonakalo yemveliso.Yinxalenye ebalulekileyo yenkqubo yokuvelisa i-mold.Umgangatho wokuchaneka kokupholisha uchaphazela ngokuthe ngqo umgangatho wokubonakala kwemveliso.Zininzi iindlela zokupolisha, njengokupolisha ngomatshini (ultrasonic), ukugulisa umatshini wokucolisa kunye nokupolisha ngesandla.Eyona nto ixhaphakileyo isetyenziswa phantsi kweemeko eziqhelekileyo, iimfuno zayo zenkqubo:

(1) Xa upholisha kwaye ugcina ukubumba, kufuneka ubone kwaye uqonde iimfuno zangaphakathi nezangaphandle zemveliso.

(2) Phambi kokupolisha, sebenzisa ifayile ukucheba umkhondo oshiywe ziinkqubo ezahlukeneyo.

(3) Ngokwesiseko sokucheba nge-whetstone, sebenzisa i-sandpaper ukusuka kwi-coarse ukuya kwi-fine ukugcina ukukhanya ngokweemfuno zemveliso.

(4) Kwiimveliso ezineemfuno ezizodwa, ezifana neendawo ezicacileyo, kufuneka zikhazimliswe nge-abrasive paste.

5

15. Ngethunjana

Gqoka isakhelo sokufa esisezantsi kunye nepleyiti yenaliti yobuso ngomngxuma we-ejector kwisikhuseli sangaphakathi esisezantsi, emva koko ugalele umngxuma ityhubhu kwisikhongozelo kwipleyiti yenaliti yobuso, kwaye ufake isikhonkwane se-ejector kwipleyiti yenaliti yobuso, isezantsi. isakhelo sokungunda kunye nokungunda kwangaphakathi okusezantsi.Qinisekisa ukuba iphini yokukhupha igungxulwe ngokuphuma komngundo wangaphakathi ongaphezulu, kwaye emva koko ufake i-ejector pin emphethweni we-ejector pin yomngxuma we-face pin plate, kwaye ubambe isikhonkwane se-ejector endaweni.

16. Indlela yokuvavanya

(1), ixhotyiswe ngezixhobo ezifana nomzimba wekrele, kwaye idibanise ukungunda.

(2) Fakela ukungunda kumatshini webhiya ngokwemigaqo yokusebenza komatshini webhiya ukwenza iinxalenye zebhiya.Ulingo lokungunda yinxalenye ebalulekileyo yenkqubo yokubumba.Ukuze uqonde ngokuchanekileyo umgangatho wokubumba ngendlela yeenxalenye zebhiya, uxinzelelo lwe-clamping, uxinzelelo lwe-injection, ubushushu bokufudumala kombane, ubushushu beziko lokunyibilika, njl njl. Kufuneka lulungiswe phambi kovavanyo lokubumba, kunye nexesha ngalinye.Yenza irekhodi yolingo.Indawo yokusebenzela yovavanyo lwebhiya mayingabi nazanjana zibandayo, kungabikho batch front, kungabikho ukushwabana, amaqamza ngaphakathi kwe-15%, kungabikho mihlathi icacileyo kunye neempawu zamanzi, kwaye umphezulu ugudile kwaye ukungunda kugudile.Ukuba iyasilela ukuhlangabezana neemfuno, kuyimfuneko ukuyilungisa kwaye uzame kwakhona.

17. Ukuguqulwa

Ngokweziphumo zovavanyo, i-mold inqunywe, kwaye i-mold iguqulwa ngokweemfuno zabathengi kunye neemfuno zendibano.Ukuguqulwa komngundo yinxalenye ebalulekileyo yokwenziwa kokungunda.Injongo yokwenziwa komngundo kukuvelisa ngobuninzi.Isantya kunye nokuchaneka kokuguqulwa kwesikhunta sichaphazela ngokuthe ngqo umgangatho wemveliso kunye nenkqubela yemveliso.Umsebenzi wokutshintsha isikhunta kukuqinisekisa ukuba ukusayina (iofisi yokuthengisa) ihlanganiswe ngaphandle kwezixhobo ezincedisayo zokulungelelaniswa kolungelelwaniso ihlangabezana neemarike (umthengi) kunye neemfuno zebhokisi ze-vibration (ngaphandle kweemfuno zokuhlobisa umphezulu).Iofisi yofakelo lobunjineli iya kuthunyelwa kwiofisi yomthengi emva kophononongo lwangaphakathi.Ngokwengxaki yokubumba ngokwayo, injineli iya kubonelela ngolwazi lokuguqulwa kwe-mold ngokweemfuno zendibano kunye neemfuno zabathengi.Izixhobo zokuguqula kufuneka zibhalwe ngokucacileyo kwaye ulwimi lube lula ukuluqonda kwaye ngaphandle kokucaciswa.Iimfuno zedatha mazicace kwaye zigqibelele, iindawo zesalathiso maziphawulelwe abo baneemfuno zesikhundla sangaphambili nasemva, kwaye inani lenzelwa abo baneemfuno zemilo.Xa injineli ingenisa ulwazi lokuguqulwa kwe-mold kubasebenzi bokuguqulwa kwe-mold, kufuneka ichaze ngokucacileyo iingongoma eziphambili zokuguqulwa kwe-mold, iinxalenye eziza kuguqulwa, iimfuno zokuguqulwa, kunye nenjongo yokuguqulwa.Emva kwesigqibo somntu, sinokuphunyezwa ngokufanelekileyo.

18. Ukukhutshwa ngundo

Emva kokuba i-mold iguqulwe, ihlolwe, isayinwe, kwaye umgangatho uhlangabezana ngokupheleleyo neemfuno zomthengi kunye neemfuno zendibano yokudlala, ukubumba kunokunikezelwa kwaye kufakwe kwimveliso.

Qhagamshelana:Andy Yang

What's app : +86 13968705428

Email: Andy@baidasy.com

Ixesha lokuposa: Nov-29-2022